Exploring the Advantages of GRP Composite Housings in Modern Business

In today’s competitive marketplace, businesses are constantly seeking advanced solutions to improve their operations and products. One such innovation is GRP composite housings, which have revolutionized various industries due to their distinctive properties and unparalleled performance. This article delves into the world of GRP composite housings, detailing their benefits, applications, and why they are considered a game-changer for numerous sectors.

What are GRP Composite Housings?

GRP, or Glass Reinforced Plastic, is a composite material renowned for its combination of durability and lightweight characteristics. When we refer to GRP composite housings, we’re speaking about enclosures crafted from this innovative material that offer significant advantages in design and functionality. These housings can be used for various applications, including but not limited to electrical enclosures, aerospace components, and marine applications.

Key Advantages of GRP Composite Housings

The adoption of GRP composite housings by businesses can be attributed to several compelling advantages:

- Durability: GRP is inherently resistant to corrosion, chemicals, and UV damage, making it ideal for long-term applications in harsh environments.

- Lightweight: Compared to traditional metal housings, GRP composite housings are significantly lighter, which can reduce transportation and handling costs.

- Thermal Insulation: GRP provides excellent thermal insulation, offering advantages in temperature-sensitive applications.

- Versatility: The molding process allows for intricate designs that can be tailored to specific needs, enhancing functionality and aesthetics.

- Cost-effectiveness: While GRP materials may have higher upfront costs, their longevity and low maintenance requirements translate into savings over time.

- Electrical Insulation: Excellent electrical insulating properties make GRP composite housings a safe choice for numerous electronic applications.

Applications of GRP Composite Housings

The versatility of GRP composite housings enables their use across various industries. Here are some prominent applications:

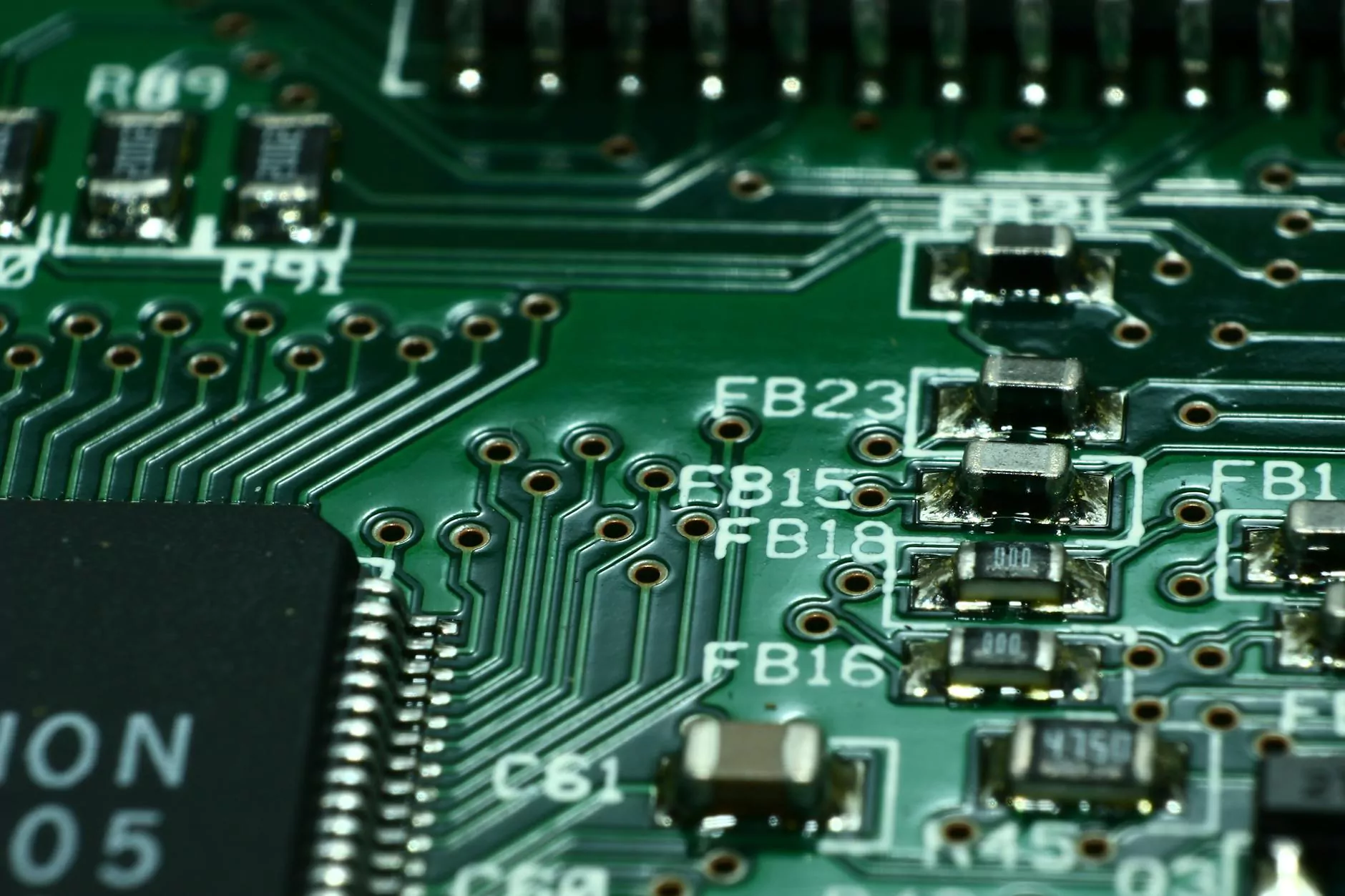

1. Electrical and Electronics

In the electrical sector, GRP casings are used for switchgear, control boxes, and transformer enclosures. Their insulation properties protect sensitive equipment while also ensuring long-term durability against environmental factors.

2. Marine Industry

Due to their resistance to corrosion and moisture, GRP composite housings are extensively used in the marine industry for housing electrical components and instruments. They are a preferred option for boats and offshore structures, ensuring reliability in challenging conditions.

3. Telecommunications

Telecommunications companies utilize GRP housings for protecting electronic equipment in remote locations. The lightweight nature facilitates easier installation and transportation.

4. Transportation

The automotive and aerospace sectors benefit from GRP housing for their lightweight properties, enhancing fuel efficiency and overall performance while maintaining structural integrity.

The Manufacturing Process of GRP Composite Housings

The production of GRP composite housings involves several critical steps that ensure the quality and performance of the final product:

- Design: Engineers design the housing using CAD software, ensuring it meets the precise requirements of the intended application.

- Material Selection: High-quality glass fibers and resin are chosen based on expected loads, environmental factors, and performance criteria.

- Molding: The design is created through either open molding or closed molding techniques, such as resin transfer molding (RTM) or hand lay-up methods.

- Curing: The housing is cured to harden the material, which establishes its structural integrity and performance characteristics.

- Finishing: Finally, the product is finished to meet aesthetic and functional requirements, which may include painting, trimming, and assembling additional components.

Why Businesses Should Choose GRP Composite Housings

Selecting GRP composite housings offers businesses a strategic advantage in achieving operational excellence. Here are several key reasons to embrace this technology:

Enhanced Performance

With superior durability and resistance to the elements, GRP reflects an innovative solution to optimize performance in various environmental conditions.

Environmental Friendliness

Many modern manufacturers focus on sustainability and eco-friendly materials. GRP housings can often be recycled, reducing the environmental impact associated with production waste.

Integration with Smart Technologies

As businesses look to incorporate smart technologies, GRP composite housings can be integrated seamlessly with communication and data collection devices, supporting modern technological advancements.

Challenges and Considerations

While GRP composite housings offer numerous benefits, businesses should consider the following challenges:

- Cost of Initial Investment: The upfront costs can be higher compared to traditional materials. However, long-term savings and benefits may justify this expense.

- Expert Heat Resistance: Depending on the formulation, some GRP materials may have limited resistance to extreme heat. It's crucial to select a type suitable for the specific application.

- Limited Repair Options: While durable, once damaged, GRP can be challenging to repair compared to metals.

Future Trends in GRP Composite Housings

The future of GRP composite housings looks promising as industries continue to evolve and technological advancements march forward. Some of the expected trends include:

1. Technological Integration

As IoT (Internet of Things) devices proliferate, GRP composite housings will increasingly serve as protective enclosures for smart devices and sensors in a variety of applications.

2. Customization

Offering bespoke solutions tailored to specific industry needs will become more common as manufacturing technology advances, allowing businesses to optimize performance and efficiency.

3. Sustainable Materials

The continued evolution of eco-friendly materials and processes will lead to the development of more sustainable GRP options, reducing environmental impact further and appealing to environmentally conscious consumers.

Conclusion

In conclusion, GRP composite housings represent a significant advancement in materials science that is transforming businesses across a variety of industries. Their benefits, including durability, cost-effectiveness, and versatility, make them a powerful tool for companies looking to optimize their operations and innovate their product offerings. By understanding the advantages and applications of GRP, businesses can make informed decisions that leverage this exceptional material for a competitive edge. Whether it's in protecting electronics, enhancing marine vessels, or supporting smart technology integration, GRP composite housings are positioned to play a crucial role in shaping the future of modern business. Embracing this technology may well define an organization's success in a growing landscape where adaptability and resilience are paramount.